A-A-55017A

Table I. Sizes and dimensions.

Size

Sleeve Expansion range 1/

Arbor length 2/ Sleeve length 2/

(inches)

(inches)

(inches)

1

3/8 to ½

4-1/2

1-1/4

2

1/2 to 9/16

5

2-1/2

3

1/2 to 11/16

5-3/4

1-1/2

4

9/16 to 21/32

6

2-3/4

5

21/32 to 3/4

6

2-3/4

6

11/16 to 1

9-1/4

2-1/2

7

3/4 to 7/8

7

3-1/4

8

13/16 to 1

9-1/4

2-1/2

9

7/8 to 1

7

3-1/4

10

1 to 1-3/8

9

4

11

1 to 1-9/16

12-1/4

3-1/4

12

1-1/4 to 1-5/8

9

4

13

1-1/2 to 2

11-1/2

5

14

2 to 2-3/4

14-1/2

5-1/2

15

2-3/4 to 3-3/4

17

6

16

3-3/4 to 5

20

7

17

5 to 6-1/2

24

8

1/ Where a range is shown, the dimensions shall be not greater than the lowest figure to not less

than the highest figure.

2/ Tolerance of arbor length shall be ±1/2 inch and sleeve length ±1/4 inch.

.

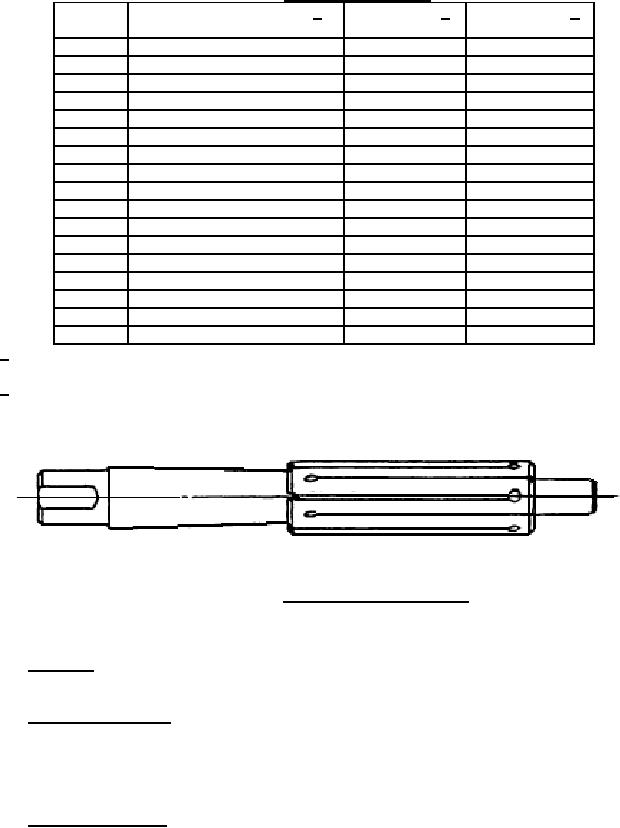

FIGURE 1. Mandrel, expanding type.

3.3 Hardness. The arbors shall have a hardness of 51 to 62 and the sleeves shall have a

hardness of 38 to 47 on the Rockwell "C" scale when measured in accordance with ASTM E18.

3.4 Identification marking. Each mandrel furnished shall be permanently marked with the sleeve

size or manufacturer's part number and the manufacturer's name or trademark of such known

character that the source of the manufacturer may be identified.

4. REGULATORY REQUIREMENTS

4.1 Recovered materials. The offeror/contractor is encouraged to use recovered materials to the

maximum extent practicable, in accordance with paragraph 23.403 of the Federal Acquisition

Regulation (FAR).

2